for Mushroom Growing

Complete Turnkey Solution For Button Mushroom Cultivation

Manufacturers, Repairs & Maintenance of: Greenhouse for Mushroom Growing, Chamber, Air- Conditioning Systems, Deep-Freezers, Cold Rooms, Refrigeration System & Allied Equipment.

Applications

This project is a modern greenhouse system specially designed for Button Mushroom cultivation.

The entire setup is created to maintain controlled temperature, humidity, airflow, and hygiene, which are essential for consistent mushroom production.

Unlike traditional open or temporary structures, this greenhouse is a fully enclosed, insulated growing environment that allows year-round production with better yield, quality, and control.

The greenhouse system is designed to:

This system can be customized according to:

This mushroom growing setup is designed as a fully enclosed and controlled growing environment, where key conditions required for Button Mushroom cultivation are maintained throughout the production cycle.

All growing conditions are maintained through controlled systems, independent of external climate variations.

The greenhouse system covers the complete mushroom

production process, including:

This makes it a complete greenhouse solution for mushroom growing, not just a room or storage space.

The Greenhouse for Mushroom Growing system follows a structured process where each stage supports the next. All activities are carried out within a controlled and hygienic environment to ensure stable production and consistent quality. This page provides a high-level overview of the complete process.

Compost Preparation

Preparation of mushroom compost using selected raw materials

Compost is conditioned to support healthy mushroom growth

Compost handling is carried out using manual or mechanical systems

This stage prepares the growing medium required for Button Mushroom cultivation.

Bag Filling and Spawning

Prepared compost is filled into 10 kg mushroom growing bags

Mushroom spawn is mixed with compost before room placement

Bags are ready for placement inside the greenhouse growing room

This step ensures uniform distribution of spawn within the compost.

Compost Preparation

Controlled Growing Room

Mushroom bags are placed on racks inside the insulated greenhouse room

Environmental conditions are maintained using refrigeration, airflow, and humidity systems

All cultivation stages take place inside the same controlled room

This allows efficient use of space and equipment.

Environmental Management

Temperature, humidity, and CO₂ levels are monitored and adjusted

Fresh air circulation and filtration are maintained

Systems can be operated manually or through automation

This ensures stable conditions throughout the production cycle.

Harvesting and Basic Handling

Button mushrooms are harvested manually at maturity

Harvesting is done in clean and controlled conditions

Mushrooms are prepared for packing after harvest

Compost preparation is the most critical stage in Button Mushroom cultivation.

The compost acts as the growing medium and food source for mushrooms. If compost quality is poor, mushroom yield and quality are directly affected.

For this reason, the Greenhouse for Mushroom Growing system includes a dedicated compost preparation infrastructure, supported by specific machines and laboratory facilities.

The compost preparation process starts in a mixing yard.

Why a mixing yard is required:

Raw materials handled in the mixing yard:

How mixing is carried out:

Without proper mixing, compost quality becomes uneven, which affects mushroom growth later.

Mixing Yard

Compose Preparation

Why bunkers are used:

Bunker system characteristics:

Why aeration is necessary in bunkers:

Machines and materials used for aeration:

Bunker System

Machines & Materials Used

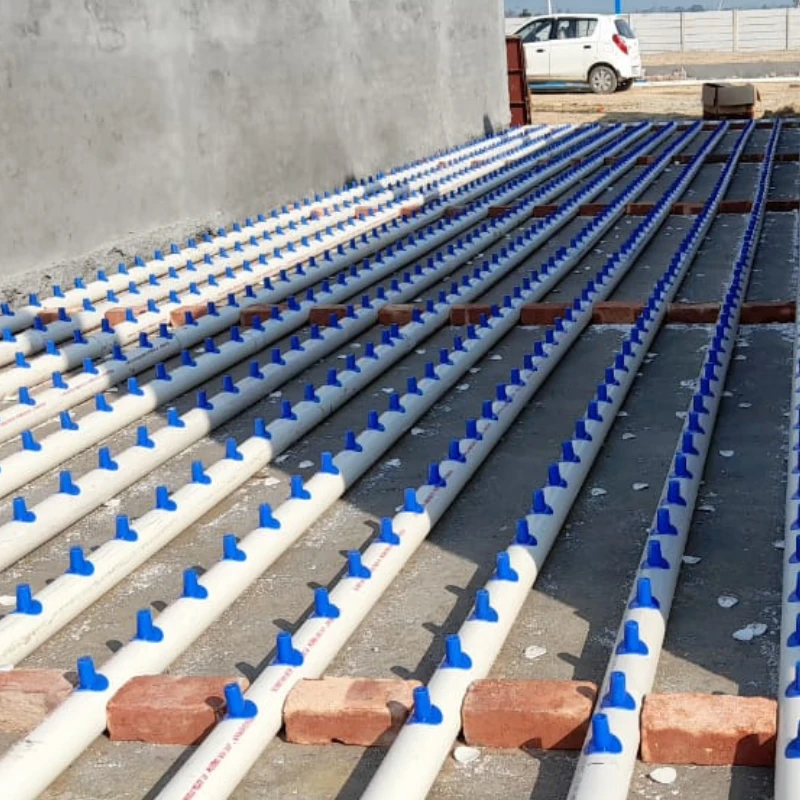

Spigots (Air Diffusers)

We’re steadily growing our footprint in India with multiple locations across the country.

Registered Address: Office No. 2, Barsat Road, Opp. Bhutter Hospital, Panipat, Haryana, 132103

Mail Us: Info@zengineering.co.in

Contact Us: +91 93551 15458

Operations Manager

Z. Engineering has been a game-changer for our business. Their cold storage solutions helped us preserve our fresh produce longer, reducing waste and improving efficiency. The custom design they provided perfectly met our needs, and the installation was seamless. We’re thrilled with their service!

Head of Procurement

We have been using Z. Engineering’s cold storage rooms for over a year now, and the results have been exceptional. The energy-efficient systems have significantly lowered our operational costs, and their team was incredibly professional throughout the process. I highly recommend them for any cold storage needs.

CEO

Z. Engineering exceeded our expectations with their top-quality deep freezers. Their products are reliable, durable, and exactly what we needed for our food processing facility. Their customer service is also outstanding—they were always available to answer our questions and provide support.